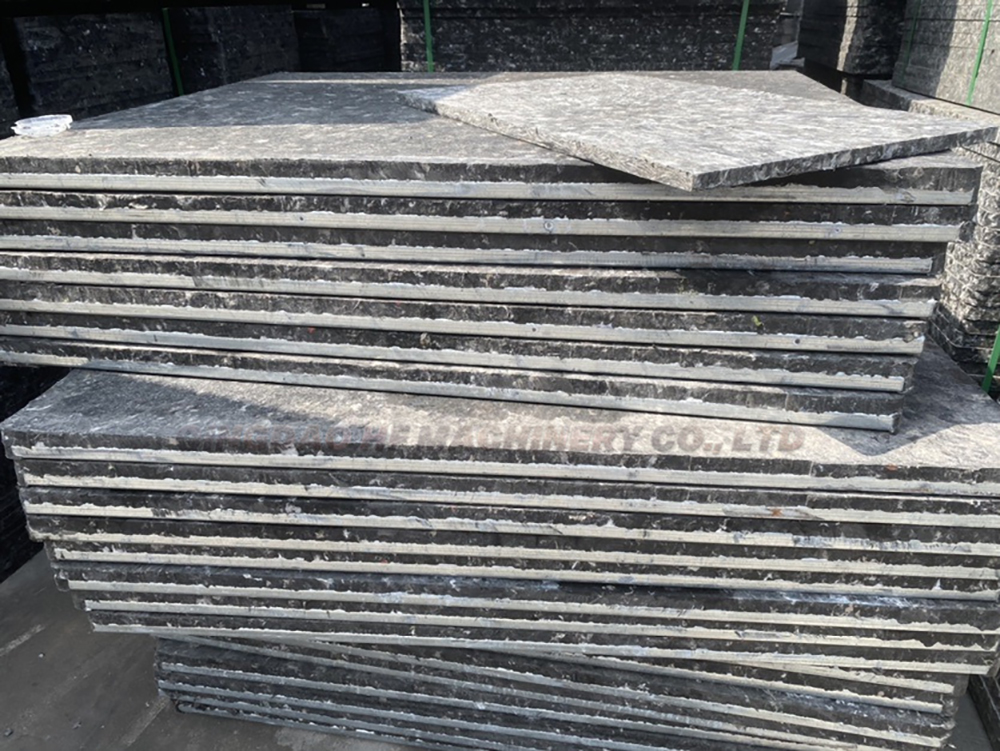

When producing concrete blocks by cement brick making machine, it is very important to choose good pallets for support and stack the finished wet blocks. In this industry, the optional pallets for concrete block machines are wooden pallets, bamboo pallets, PVC pallets and GMT pallets. Made of fiber as reinforcing material and base of thermoplastic resin, the GMT (Glass Mat Reinforced Thermoplastics) is strong enough for wet bricks support after the special heating and pressurizing.

GMT pallet for concrete block is made of fiber as reinforcing material and base of thermoplastic resin through mould pressing.It is a kind of plastic brick pallet for concrete block. It is currently an extremely popular plastic pallet in the world and is consider one of the most promising pallet today.

GMT is a new kind of plastic brick blocks pallet with many advantages, so it is very useful for concrete block machines production. This glass reinforced pallet is currently an extremely popular composite materials in the world, and is considered one of the most promising new materials in the 21th century. As one kind of the plastic brick pallet, GMT blocks pallet is superior to PVC brick pallet, bamboo pallets and wooden brick pallet. Here we introduce the features and advantages of GMT pallets.

The GMT stands for Glass Mat Reinforced Thermoplastics material has been widely used in automobile industry (such as bumper, motor base), construction industry (like formwork) etc. This GMT material is proved to be rigidity, toughness, and recyclable characteristics. Our GMT brick pallets for concrete block production are made from this material. Therefore, it can be as solid as reinforced concrete, for the fiber in the pallet is structured like reinforced concrete.

1、Lightweight: The density of brick machine GMT pallet for concrete block is 1200kg/m3. Compared with normal PVC brick pallet(1750kg/m3), the weight of GMT pallet of concrete block is about 70% of PVC pallet.

2、Long lifetime: The concrete block GMT pallets can last for 8-10 years, so it is durable. For the lifetime, the GMT is better than PVC pallet and wooden pallet.

3、High loading capacity: It’s lower flexure of our GMT pallet for concrete block.

4、High impact resistance: When doing the impact resistance test, hitting our concrete block GMT pallets will not damage the GMT pallets.

5、Waterproof: Our block brick GMT pallet used for Hongfa concrete block machine production is plastic pallet, so it is waterproof. Therefore, in this feature, GMT pallets are superior to wooden pallets or bamboo pallets.

6、Corrosion resistance: Our GMT pallets for concrete block making is plastic pallet, so it is corrosion resistance. In this way, it can be durable and with less maintenance cost.

7、Abrasion resistant: The abrasion resistance of our GMT pallets for concrete block usage good, not easier to be bent and broken. So it is better than PVC pallet and wood pallet so the lifetime of GMT pallets can last longer.

Customize size: We are pleased to customize the GMT pallets according to your cement brick making machine moulding size.

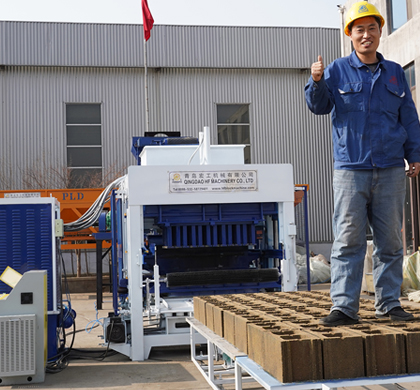

Block machines play a crucial role in modern construction, facilitating the production of various types of blocks used in buildings, roads, and infrastructure projects. To ensure optimal efficiency and longevity of these machines, it's essential to unders

There are several types of block machines used in various industries for producing different types of blocks, such as concrete blocks, cement blocks, and interlocking blocks. Some common types include:

The first step in maximizing the potential of a brick making machine is to select the right machine for the job. Consider factors such as the size of the bricks you need to produce, the production capacity required, and the specific features and capabilit

Whether for inquiries for inspections and

maintenance, for individual plant optimizations or

extensions, or spare and wear parts.

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.